A better explanation is that DOGE is functioning as a stress test of the federal bureaucracy.

Stress tests are not designed to produce immediate, permanent fixes. They are designed to apply pressure and observe outcomes: where systems bend, where they break, where they resist, and where supposed constraints turn out to be optional once incentives change. It is a drive to gather data, not repair issues.

Under this model, efficiency gains are not the primary goal. They are signal, evidence of latent capacity revealed under load. Resistance, delay, panic, and narrative hostility are also signal. They show where authority actually resides and which processes exist because they are necessary, versus merely habitual.

The Social Security Administration results fit this model precisely. When pressure was applied, performance improved quickly and measurably. That does not prove the system is now permanently fixed. It shows something more revealing: The capacity was there all along. //

This interpretation aligns closely with how Elon Musk has repeatedly operated across very different domains.

Musk does not treat institutions as abstract ideals. Thinking like an engineer, he treats them as systems that must be tested under real conditions. His approach favors empirical stress over theoretical reassurance and exposure over simulation.

One of the clearest expressions of this philosophy is SpaceX’s use of the acronym RUD, “rapid unscheduled disassembly,” referred to by most people as a big old explosion. Rockets are pushed until they fail. Failure is not an embarrassment, but rather a valuable data collection moment. Each breakdown reveals load-bearing assumptions that no white paper can surface.

The goal is not to avoid failure at all costs. The goal is to fail fast enough, visibly enough, to learn where the system’s true limits are, and to learn it quickly.

Viewed through this lens, DOGE’s behavior becomes coherent. //

From a stress-test perspective, controversy is not proof of failure. It is proof that pressure reached something structural.

Boeing aircraft, including the 747, 757, 767, and 777, all take on a sleeker, forward-stretching and beak-like shape at the front, while the Airbus planes, such as the A320, A330, A340, A350, and A380 families, have a rounder front profile with a smooth curve from top to bottom. This difference isn't just cosmetic or a preferred choice in design — it's the product of decades of engineering philosophy and aerodynamics history.

Boeing, since 1916, has continued to follow its engineering legacy of pointed noses borrowed from the earliest B17 and 747 aircraft. This was during a time when wind tunnel experimentation was big among the aircraft engineers who believed that a tapered, pointier nose helps reduce drag and cut through wind faster. This design had also become Boeing's signature look and straying away from it would've meant compromising the brand's identity.

Airbus, on the other hand, was born much later in the 1970s, in an era where aerodynamics history had evolved and computer modeling introduced a new idea that at subsonic speeds below Mach 1, a smaller, rounder nose shape actually helps reduce drag and smooth airflow. As a result of this new understanding, Boeing began embracing the compact, dolphin style that now defines its fleet with the arrival of the 787. //

At subsonic speeds, the shape of the aircraft matters less than it does at supersonic or transonic speeds, where a needle-like nose is needed to cut through pressure fronts to avoid the harsh drag that builds at higher Mach levels. Thus, computational modeling prescribed a shorter, rounder shape for lesser skin friction and to minimize the total wetted surface area to facilitate the movement of air particles around it. This is why Airbus has kept its round, bubble shape that is refined for laminar flow, and Boeing is following suit.

Open channel flow monitoring is a long-established technique used to measure the flow rate of water in irrigation channels, streams, stormwater systems, and wastewater treatment facilities. Unlike closed-pipe systems, open channels rely on gravity rather than pressure, making accurate measurement dependent on the relationship between water level (stage) and flow rate.

NASA and The Ohio State University have created a brand-new metal called GRX-810, a printable superalloy engineered to withstand extreme heat inside jet and rocket engines. It is being called one of the most significant breakthroughs in high-temperature materials in recent years. NASA says GRX-810 is twice as strong as the best 3D printed superalloys available today, more than a thousand times more durable at high temperatures, and twice as resistant to oxidation. The team demonstrated it using laser 3D printing and believes it could lead to stronger and longer-lasting parts for airplanes, spacecraft, and high-performance engines.

GRX-810 is what materials scientists refer to as an oxide dispersion strengthened alloy. In essence, it is a nickel, cobalt, and chromium-based metal reinforced with tiny ceramic particles. These nano-oxides, specifically yttrium oxide (Y₂O₃), make up about one percent of the alloy by weight. NASA coats the metal powder with these nanoscale oxides before printing, and then fuses the powder together layer by layer using laser powder bed fusion.

As the part solidifies, the oxide particles remain locked inside the metal matrix like rebar in concrete. This reinforcement stops the metal from deforming or cracking when exposed to both high heat and heavy load. The alloy’s recipe involves nine different metallic elements along with the nano-oxides, and this combination was optimized through computational alloy design rather than trial and error.

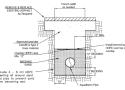

Dry coarse-grained sand may be used as a substitute for the insulation required by code in a buried pipe situation. The sand should have a maximum particle size of ¼” and a moisture content of 1% or less. The thermal conductivity, K, of coarse, dry sand varies between 0.15 – 0.25 W/mK. Converting to Imperial units = 1.7 Btu.in/ft2.oF.hr. R-value is the reciprocal of conductivity, therefore, the R-value of coarse dry sand = 0.58 ft2.oF.hr/Btu.in.

1-inch of fiberglass insulation with a conductivity of 0.27 has an R-value of 3.70. Conversely, 6″ of dry coarse sand has an R-value of 3.46; 12″ would have an R-value of 6.92.

In addition, some provisions need to be made to keep the insulating sand as dry as possible.

The answer to the ever-shrinking pool of qualified engineers is (drum roll, please) more I/O. That was just one takeaway from our second Studio Master Class hosted by Jay Tyler with panelists Rob Bertrand, CEO for Inrush, and Alex Bonello, Insoft (HDVMixer).

The premise is that the more I/O, the more pathways you have to the components in the airchain for troubleshooting and fixing problems remotely. Rob pointed out that adding more Blade I/O seems like overkill at first, but it’s often impossible to troubleshoot and correct problems remotely without that access. “There are not enough of us out there to keep all the stations going that need help. We’re going in and constantly thinking, ‘What can we leverage to ensure that we’re able to respond wherever we are, to whatever problem comes up for a client?’” commented Rob.

“Unfortunately, we’re not growing new broadcast engineers,” agreed Jay, adding that Blades decentralize the Ethernet switch as a practical, affordable way to get to problems quickly in the absence of a nearby engineer.

Today, let's look at who's to blame for all the cars that insist on shifting for themselves. Arguably, the earliest blame-havers could be Louis-Rene Panhard and Emile Levassor, who were about to show off their new automatic transmission in 1894 when the thing just broke, forcing them to turn the demonstration into a Ted Talk with a chalkboard.

Then, in 1904, when concepts such as radio, television, and TikTok were still yet to be realized, two brothers with the last name of Sturtevant were plugging away at the Sturtevant Mill Company in Boston, patenting all sorts of industrial machines, including an automatic transmission and the awesome-sounding "Double Carburetor for Explosive Engines." Their primitive automatic only had two speeds, sort of like a GM Powerglide, but its operation was much different than later automatic transmissions and their weird interiors laden with forbidden mysteries.

The Sturtevant automatic used a pair of clutches attached to spring-loaded weights.

Read More: https://www.jalopnik.com/1902889/automatic-transmission-history-first-car/

For a more concise overview, check out Sabin Civil Engineering's video, "Automatic Transmission, How it works?" on YouTube.

Read More: https://www.jalopnik.com/1962277/how-automatic-transmission-knows-when-to-shift/

Iran’s wind catchers stand as a reminder of how ancient civilisations have adapted to the region’s harsh desert environment.

Just who are the greatest aerospace engineers of all time? The ability to fly has long been an ambitious quest for mankind. Many centuries have been spent trying to master the art, as such there have been many aerospace engineers with a profound and lasting impact. Here at MNB Precision we have compiled a list of both the greatest engineers and the greatest aerospace engineers. Ranging from the most famous and prominent to some lesser known yet still crucial figures, these are some of the best professionals in the field.

Ryan, Craig. Sonic Wind. New York: Livewright Publishing, 2018. ISBN 978-0-631-49191-0.

John Paul Stapp's family came from the Hill Country of south central Texas, but he was born in Brazil in 1910 while his parents were Baptist missionaries there. After high school in Texas, he enrolled in Baylor University in Waco, initially studying music but then switching his major to pre-med. Upon graduation in 1931 with a major in zoology and minor in chemistry, he found that in the depths of the Depression there was no hope of affording medical school, so he enrolled in an M.A. program in biophysics, occasionally dining on pigeons he trapped on the roof of the biology building and grilled over Bunsen burners in the laboratory. //

It was not until the 1960s that a series of mandates were adopted in the U.S. which required seat belts, first in the front seat and eventually for all passengers. Testifying in 1963 at a hearing to establish a National Accident Prevention Center, Stapp noted that the Air Force, which had already adopted and required the use of seat belts, had reduced fatalities in ground vehicle accidents by 50% with savings estimated at US$ 12 million per year. In September 1966, President Lyndon Johnson signed two bills, the National Traffic and Motor Vehicle Safety Act and the Highway Safety Act, creating federal agencies to research vehicle safety and mandate standards. Standing behind the president was Colonel John Paul Stapp: the long battle was, if not won, at least joined.

Stapp had hoped for a final promotion to flag rank before retirement, but concluded he had stepped on too many toes and ignored too many Pentagon directives during his career to ever wear that star. In 1967, he was loaned by the Air Force to the National Highway Traffic Safety Administration to continue his auto safety research. He retired from the Air Force in 1970 with the rank of full colonel and in 1973 left what he had come to call the “District of Corruption” to return to New Mexico. He continued to attend and participate in the Stapp Car Crash Conferences, his last being the Forty-Third in 1999. He died at his home in Alamogordo, New Mexico in November that year at the age of 89.

In his later years, John Paul Stapp referred to the survivors of car crashes who would have died without the equipment designed and eventually mandated because of his research as “the ghosts that never happened”. In 1947, when Stapp began his research on deceleration and crash survival, motor vehicle deaths in the U.S. were 8.41 per 100 million vehicle miles travelled (VMT). When he retired from the Air Force in 1970, after adoption of the first round of seat belt and auto design standards, they had fallen to 4.74 (which covers the entire fleet, many of which were made before the adoption of the new standards). At the time of his death in 1999, fatalities per 100 million VMT were 1.55, an improvement in safety of more than a factor of five. Now, Stapp was not solely responsible for this, but it was his putting his own life on the line which showed that crashes many considered “unsurvivable” were nothing of the sort with proper engineering and knowledge of human physiology. There are thousands of aircrew and tens or hundreds of thousands of “ghosts that never happened” who owe their lives to John Paul Stapp. Maybe you know one; maybe you are one. It's worth a moment remembering and giving thanks to the largely forgotten man who saved them.

-

Independent cooling performance and system economy of A-CAES systems were studied.

-

Three A-CAES systems were proposed for chilled water, cold air, and hybrid supply.

-

Improved cooling capacity can reach 20.33, 40.05, and 45.05GJ in cooling season.

-

A-CAES hybrid system was the optimum system for cooling supply.

Yuchen Jin @Yuchenj_UW

judging an engineer by age is BS

- Linus Torvalds wrote Linux at 21

- Steve Wozniak built Apple I at 25

- Palmer Luckey created Oculus VR at 20

- Vitalik Buterin designed Ethereum at 19

- Mark Zuckerberg coded Facebook at 19

Looking back, I realize that 18-25 is the peak time.

"The young do not know enough to be prudent, and therefore they attempt the impossible – and achieve it, generation after generation."

I spent many years conducting root cause analyses and teaching major corporate employees, mostly engineers, how to do root cause analysis. One of the tools for root cause analysis is what some call "5 Whys," but I always called a "Why-Why Analysis," as sometimes it may take two "Whys" and others, ten. In this case, there are too few houses. But they don't ask or answer the next question: Why? //

When asked, "How do you know when you've arrived at a root cause," my stock reply was, "When you arrive at the point where some person or group of people made a decision, that's likely to be your root cause." //

Percyisacat

4 hours ago

Where did they find 1100 sq feet for $2500 a month in Campbell?????? My son lived in Santa Clara, and paid over $3,000 a month for rent.

This calculator determines the absolute pressure at the pump impeller. NPSHA must exceed the NPSHR (net positive suction head requirement specified by the pump manufacturer or caviation and/or loss of prime will occur.

The first form calculates the pressure or friction loss along a given length of pipeline with a specified inside diameter. The second form calculates the minimum pipe size to limit pressure loss to a specified value.

Additional friction pressure losses occur due to fittings. These losses in-effect add extra additional length to the total pipeline. Use this calculator to estimate how much additional length needs to be added to the overall pipe length below in order to estimate these additional losses. Learn more about the units used on this page.

Here's the math behind making a star-encompassing megastructure.

In 1960, visionary physicist Freeman Dyson proposed that an advanced alien civilization would someday quit fooling around with kindergarten-level stuff like wind turbines and nuclear reactors and finally go big, completely enclosing their home star to capture as much solar energy as they possibly could. They would then go on to use that enormous amount of energy to mine bitcoin, make funny videos on social media, delve into the deepest mysteries of the Universe, and enjoy the bounties of their energy-rich civilization.

But what if the alien civilization was… us? What if we decided to build a Dyson sphere around our sun? Could we do it? How much energy would it cost us to rearrange our solar system, and how long would it take to get our investment back? Before we put too much thought into whether humanity is capable of this amazing feat, even theoretically, we should decide if it’s worth the effort. Can we actually achieve a net gain in energy by building a Dyson sphere? //

Even if we were to coat the entire surface of the Earth in solar panels, we would still only capture less than a tenth of a billionth of all the energy our sun produces. Most of it just radiates uselessly into empty space. We’ll need to keep that energy from radiating away if we want to achieve Great Galactic Civilization status, so we need to do some slight remodeling. We don’t want just the surface of the Earth to capture solar energy; we want to spread the Earth out to capture more energy. //

For slimmer, meter-thick panels operating at 90 percent efficiency, the game totally changes. At 0.1 AU, the Earth would smear out a third of the sun, and we would get a return on our energy investment in around a year. As for Jupiter, we wouldn’t even have to go to 0.1 AU. At a distance about 30 percent further out than that, we could achieve the unimaginable: completely enclosing our sun. We would recoup our energy cost in only a few hundred years, and we could then possess the entirety of the sun’s output from then on. //

MichalH Smack-Fu Master, in training

4y

62

euknemarchon said:

I don't get it. Why wouldn't you use asteroid material?

The mass of all asteroids amounts to only 3% of the earth's moon. Not worth chasing them down, I'd guess. //

DCStone Ars Tribunus Militum

14y

2,313

"But [Jupiter]’s mostly gas; it only has about five Earth’s worth of rocky material (theoretically—we’re not sure) buried under thousands of kilometers of mostly useless gas. We'd have to unbind the whole dang thing, and then we don’t even get to use most of the mass of the planet."

Hmm. If we can imagine being able to unbind rocky planets, we can also imagine fusing the gas atmosphere of Jupiter to make usable material (think giant colliders). Jupiter has a mass of about 1.9 x 10^27 kg, of which ~5% is rocky core. We'd need to make some assumptions about the energy required to fuse the atmosphere into something usable (silicon and oxygen to make silicates?) and the efficiency of that process. Does it do enough to change the overall calculation though? //

Dark Jaguar Ars Tribunus Angusticlavius

9y

11,066

The bigger issue is the sphere wouldn't be gravitationally locked in place because the sun is cancelling it's own pull in every direction. Heck even Ringworld had to deal with this flaw in the sequel. That's why these days the futurists talking about enclosing the sun recommend "Dyson swarming" instead.

Edit: A little additional note. You can't really get the centrifugal force needed to generate artificial gravity across an entire sphere like you can with a ring. A swarm doesn't negate this. If you orbit fast enough to generate that artificial gravity, you're now leaving the sun behind. Enjoy drifting endlessly! No, rather each of these swarm objects are just going to have to rotate themselves decently fast.

A few months ago, our AM radio hot dog experiment went mildly viral. That was a result of me asking my Dad 'what would happen if you ground a hot dog to one of your AM radio towers?' He didn't know, so one night on the way to my son's volleyball practice, we tested it. And it was awesome.

There's a video and some pictures in my hot dog radio blog post from back in March.

Fast forward a few months and one Open Sauce later, and Jay from Plasma Channel visited us in St. Charles, MO, for round two—where my Dad and I were prepared to measure (almost) everything: SWR, RF forward power, SDR on site, AM field intensity 25km (16mi) away, meat thermals, and—courtesy of Jay—some taste testing!

Industrial networking is vital to today’s manufacturing landscape. From different types of networks to key components and best practices, this guide will help you navigate the intricacies of industrial Ethernet networking. See video.

“We just had a midair,” the pilot of the Hawker is heard saying in an audio recording posted on LiveATC.net, which shares live and archived recordings of air traffic control radio transmissions.

Someone in the control tower responds by saying, “Say what?”

“You guys cleared somebody to take off or land, and we hit them on a departure,” the Hawker pilot says.

The recent accident in Houston is just the latest noteworthy instance in what a major New York Times investigation this summer determined to be “an alarming pattern of safety lapses and near misses in the skies and on the runways in the USA.” According to internal records of the Federal Aviation Agency, the Times reported that these safety lapses and near misses occurred as a “result of human error.” The Times report further revealed that “runway incursions” of the sort described above have nearly doubled, from 987 to 1732, despite the widespread proliferation of advanced technologies. //

While the disturbing decline in aviation safety is complex and multifaceted, we identified two major contributing factors that have received scant media attention. The first such factor is the likely contribution of disastrous COVID-era policies to the staffing shortage of many air traffic control rooms. The second factor is that aggressive affirmative action policies implemented during the Obama administration have resulted in a catastrophic collapse in the quality of controllers. In short, COVID policies have gutted the quantity of air traffic controllers, and diversity policies have gutted the quality of air traffic controllers, creating unprecedented danger for the aviation industry. //

The implications of these findings reach far beyond the scope of aviation, as important as this industry is. Rather, the collapse of the aviation industry must be understood in the context of a broader collapse in our ability to maintain the infrastructure of a First World society. This is a major and significant trend that we highlighted years ago in our coverage of the repeated failures of Texas’ electric power grid.